First of all, let me give you some idea about corrosion; Corrosion is gradually destruction of the materials by chemical reaction with their surrounding environment. When we look at any process industries, they are continuously handling different types of chemicals that react with the materials (metals) and degrade those materials.

SO WHAT is the Solution? Cheaper, Effective, Long-Lasting, Resistant to highly corrosive chemicals ?

Its “ANTI- CORROSIVE CERAMICS” called “CORROSION RESISTANT BRICK “

People working in Indian industry are generally got confused while they heard other names of the Corrosion Resistant Brick. Let me simplify the same.

[SYNONYMS, OTHER TERMS of CORROSION RESISTANT BRICK: ACID RESISTANT BRICK, ACID PROOF BRICK, ANTI-ACID BRICK, ALKALI RESISTANT BRICK, ALKALI PROOF BRICK, CHEMICAL RESISTANT BRICK, CHEMICAL PROOF BRICK]

They are also confused about the difference between Bricks and Tiles

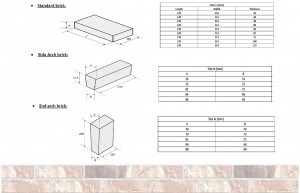

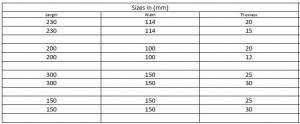

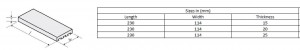

- Bricks are having thickness > 20 MM

- Tiles are having thickness < 20 MM

- There is no major difference between them except thickness; all the technical specifications and standards are same.

[SYNONYMS, OTHER TERMS of CORROSION RESISTANT TILES: ACID RESISTANT TILES, ACID PROOF TILES, ANTI-ACID TILES, ALKALI RESISTANT TILES, ALKALI PROOF TILES, CHEMICAL RESISTANT TILES, CHEMICAL PROOF TILES]

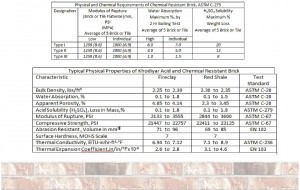

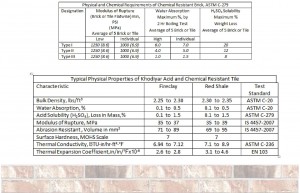

What is Acid-Resistant Brick and tile, Its specifications?

Acid Brick are having resistance properties to almost all kinds of chemicals, except Hydrofluoric acid. It can resist highly corrosive acids and alkalis.

Why and when Acid Resistant Brick required?

- Low Water Absorption in order to minimize penetration of corrosive chemicals

- High Silica SIO2 in order to achieve High Chemical Resistance

- High Compressive strength and High Flexural Strength when being used in floors with heavy vehicles moving.

- High abrasion resistance and good thermal shock resistance are required